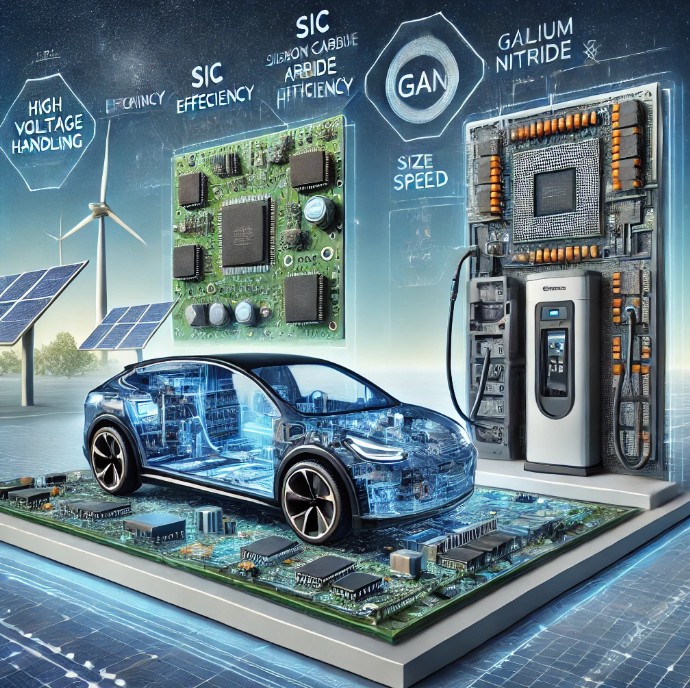

The electric vehicle market is evolving rapidly, driven by the demand for greater efficiency, extended range, and faster charging. At the heart of this revolution lies the choice of semiconductor materials for power electronics: Silicon Carbide (SiC) and Gallium Nitride (GaN). Both materials offer compelling advantages over traditional silicon but cater to slightly different applications within the EV ecosystem.

Silicon Carbide (SiC): A Powerhouse for High Voltage Applications

SiC is renowned for its ability to handle high voltages and temperatures, making it ideal for powertrain components like inverters, onboard chargers, and DC-DC converters. SiC devices boast lower switching losses and higher thermal conductivity, which translates to improved efficiency and reduced cooling requirements. These characteristics are particularly advantageous for high-performance EVs and heavy-duty vehicles that demand robust power solutions. However, the cost of SiC devices remains a barrier, though prices are gradually decreasing with advancements in manufacturing.

Gallium Nitride (GaN): A Contender for Compact Efficiency

GaN, on the other hand, excels in high-frequency, low-to-medium voltage applications. Its smaller size and faster switching speeds enable compact and lightweight designs, making it a preferred choice for EV chargers and auxiliary systems. GaN's ability to operate efficiently at high frequencies also reduces the size of passive components, further enhancing its appeal for space-constrained applications. However, GaN's lower voltage threshold limits its use in high-power drivetrain systems.

The Future of EV Power Electronics

While SiC is currently dominating high-power applications, GaN is carving out its niche in lower-power, high-efficiency systems. The future likely holds a coexistence of these technologies, with each addressing specific needs within the EV market. As production scales and costs decline, both SiC and GaN will play pivotal roles in shaping the next generation of electric vehicles.